Industrial Coating Division

AL Duqum Al Masiya Ent (ADAM) have diversified our business activities to cater various other services including:-

Industrial Coating Services, Mechanical and Fabrication activities, Trading and Calibration of oilfield instruments and appurtenances, Trading of Consumer Products and a Vehicle Rental division.

Industrial Coating Division Activities

Blasting and Painting

ADAM Blasting & Painting division is experienced in applying specialized in Coating & Blasting for Process plants, Power plants, Storage vessels, Storage Tanks, Pipe lines and Structures;

Our team Specialized in Epoxy, Belzona and Fire proofing coating. Application of Marine & Industrial grit blasting and painting Intumescent coating – Spray application method Floor Concrete coating On site, in-site repairs of pipe works. ADAM is an approved applicator of Jotun and Carboline product.

Intumescent coating

Intumescent coatings are a type of fire protection coating that expands when exposed to heat or flames. These coatings are designed to provide passive fire protection by forming an insulating char layer that helps to delay the spread of fire and protect the underlying substrate from high temperatures. They are widely used in various industries, including construction, oil and gas, transportation, and manufacturing.

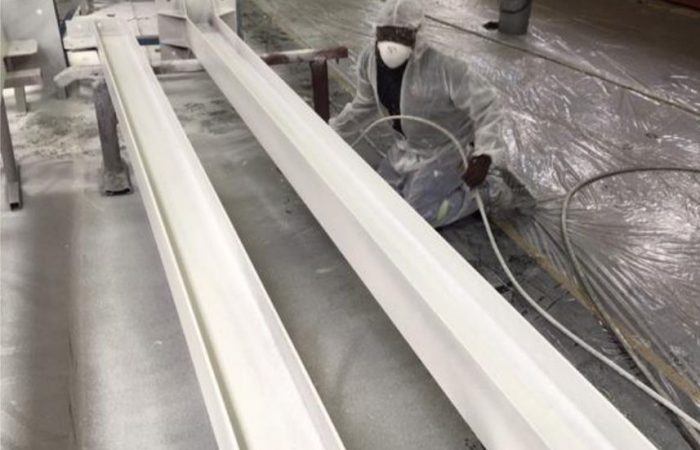

GRE lining

GRE lining, which stands for Glass Reinforced Epoxy lining, is a commonly used solution in the oil and gas industry for protecting pipelines and equipment from corrosion and abrasion. This lining system consists of a composite material comprising a thermosetting resin matrix reinforced with glass fibers. GRE lining offers several advantages in the oil and gas sector, including excellent chemical resistance, high mechanical strength, and superior durability. It provides a protective barrier against corrosive substances, such as hydrogen sulfide and carbon dioxide, commonly found in oil and gas production environments. The GRE lining’s robust construction ensures its ability to withstand extreme temperatures, pressures, and harsh operating conditions, making it ideal for offshore and onshore applications. With its remarkable corrosion resistance and mechanical properties, GRE lining contributes to the longevity, reliability, and efficiency of oil and gas infrastructure.

Tank Cleaning

Tank cleaning plays a critical role in maintaining safety, efficiency, and compliance within the oil and gas industry. Tanks used for storing crude oil, petroleum products, or hazardous chemicals require regular cleaning to remove accumulated sludge, sediment, and other contaminants. The tank cleaning process involves a combination of mechanical methods, such as high-pressure water jetting and scraping, as well as chemical cleaning agents to dissolve stubborn deposits. Proper tank cleaning helps prevent cross-contamination, ensure product quality, and reduce the risk of corrosion or equipment failure. It also allows for inspection and maintenance activities to be carried out effectively. In addition to routine cleaning, tanks may undergo specialized cleaning techniques, such as confined space cleaning or automated tank cleaning systems, depending on the specific requirements of the tank and the substances stored within it. Implementing thorough tank cleaning practices is crucial for upholding operational efficiency, regulatory compliance, and environmental stewardship in the oil and gas industry.

Insulation works

Insulation works providing thermal protection, energy efficiency, and personnel safety across various operations. Insulation is used to minimize heat transfer, prevent condensation, and maintain the desired temperature within equipment, piping, and storage tanks. In this industry, where extreme temperatures and harsh environments are common, insulation helps to conserve energy, reduce heat loss, and optimize process efficiency. It also helps prevent thermal expansion and contraction, which can lead to equipment failure or structural damage. Moreover, insulation enhances safety by reducing the risk of burns or accidental contact with hot surfaces. Insulation materials such as mineral wool, fiberglass, or foam insulations are chosen based on their specific thermal properties and resistance to chemicals, moisture, and fire. Properly designed and installed insulation systems are crucial for minimizing heat loss, maintaining process stability, and ensuring the safe and efficient operation of oil and gas facilities.

Floor coating

Floor coatings providing a durable and protective surface for industrial floors. These coatings are designed to withstand heavy foot traffic, equipment movement, chemical exposure, and mechanical stress commonly encountered in oil and gas facilities. Floor coatings create a seamless and resistant barrier that enhances safety, facilitates maintenance, and improves overall productivity. They offer excellent resistance to abrasion, impact, chemicals, and oil spills, thereby preventing damage to the underlying concrete substrate. Additionally, floor coatings can be formulated with anti-slip properties to reduce the risk of slips, trips, and falls, even in wet or oily conditions. The application of floor coatings in the oil and gas industry helps maintain a clean and hygienic environment, enhances visibility, and contributes to the longevity and performance of the facility’s flooring system.

Scaffolding works

Scaffolding works are an integral part of construction, maintenance, and renovation projects in various industries, including the oil and gas sector. Scaffolding refers to the temporary structures erected to provide a safe and stable platform for workers to perform tasks at elevated heights. It enables access to hard-to-reach areas, such as high-rise structures, industrial plants, or offshore platforms. Scaffolding systems are designed to support the weight of workers, tools, and materials, ensuring efficient workflow and minimizing the risk of accidents or falls. The construction of scaffolding involves assembling a framework of metal pipes, tubes, or modular components, along with platforms, guardrails, and ladders. It requires skilled personnel who adhere to strict safety regulations and industry standards. Scaffolding not only facilitates work at height but also allows for the transportation of equipment and materials, making it an essential element in the oil and gas industry’s operations. Properly designed, erected, and maintained scaffolding systems provide a safe working environment, enabling workers to carry out their tasks effectively and efficiently.